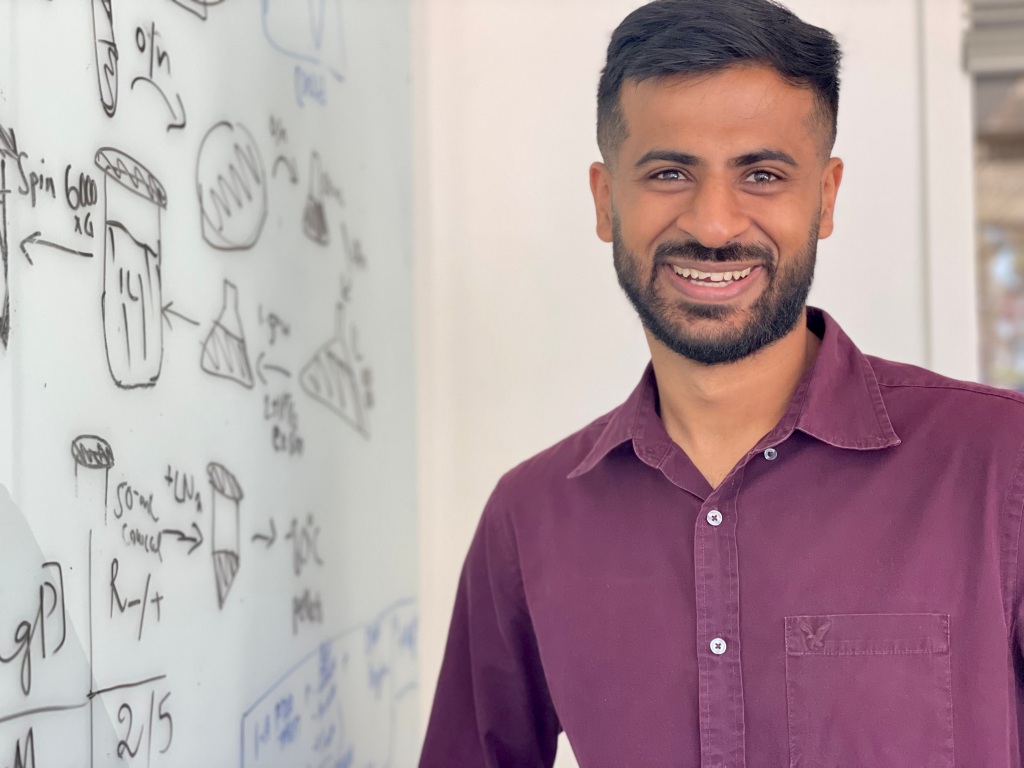

I recently had the opportunity to sit down with Ravi Chawla, a postdoctoral fellow at Scripps Research, who is currently in the very early stages of forming ChakraTech (formerly known as WheelBio). This company is dedicated to using microbes to make completely and naturally degradable bioplastics from greenhouse gases, potentially solving the problem of plastic pollution! He recently took third place in a pitch competition through Aquillius, and will be utilizing their lab space as he forms his company.

Over the course of our wide-ranging conversation, we covered topics like the risks associated with forming a startup, pushing through difficulties with commercializing this product, and building a resilient industrial biotech scene in San Diego.

It was a fascinating conversation, and a great opportunity to talk to someone at the forefront of both science and business, working to get a brand-new, innovative company off the ground.

If you’d like to learn more, you can reach Ravi on his LinkedIn.

I’m primarily interested in the concept of resilience – whether personal, communal, or societal. What does the concept of resilience mean to you?

That’s an interesting question!

The word resilience to me refers to the spirit of persevering in the presence of difficulty. To be resilient, therefore, means to prevail or succeed despite all the odds!

Resilience is a profound concept in philosophy and psychology, embodying a character marked by persistence in responding to challenges or hardships. Often, individuals are not immediately aware of their own resilience; it becomes apparent through their actions and reactions over time. I am deeply inspired by individuals who exhibit perseverance and courage. Their stories of overcoming adversity not only resonate with me, but also fuel my own aspirations and strengthen my own commitment to face challenges with similar bravery.

Achieving anything significant, particularly when it involves paradigm-shifting innovations, demands immense determination. And interestingly, resilience extends beyond personal tenacity; it is deeply rooted in the collective strength drawn from one’s support network and community. Therefore, it’s crucial to be in the company of people who offer unwavering support and encouragement during challenging times. This belief forms the cornerstone of my philosophy on resilience.

Overall, resilience is a harmonious interplay between personal commitment and communal support, underpinned by strategic thinking, persistent action, and reliable execution, all directed towards a common goal.

So seeing a vision, and then doing whatever it takes to get there.

Yes, by going full force!

I attended an Anglo-Vedic middle school in India, where I drew much inspiration from ancient Indian texts. I am often reminded of a powerful quote by the late 19th-century Indian Hindu monk Swami Vivekananda, “Arise, awake, and stop not till the goal is reached.”

This quote, which was inspired by a shloka from the Katha Upanishad, continues to resonate with me.

Your background is an interesting one. You’re from a small town in India but became a chemical engineer. How has this background influenced your career?

Growing up in a small town was a formative experience for me. Limited opportunities translate into limited expectations and limited aspirations. My dad was just happy that I finished 10th grade.

When I finished 10th grade, my dad brought me a job he saw in the newspaper for a position as a constable. I was like, “do I look like someone who could do that? I’m the biggest nerd that exists!” But I, somehow, have always had a determination to challenge the status quo and defy the norm. Perhaps, I get this trait from my mom, who I’ve always thought to be both fearless and a force of nature, and has always been a tremendous source of inspiration for me! Anyway, this drive led me to successfully persuade my family to relocate to a larger city, Chandigarh, that opened the door to more educational opportunities.

After relocating to Chandigarh, I completed 12th grade and appeared for the engineering school entrance exams. My interests primarily lay in physics, chemistry, and mathematics. However, when someone suggested a career in chemical engineering, I was initially distraught. Even though I was preparing for engineering school, I had no understanding of what any of the engineering fields entailed. Among my peers, the prevailing belief was that chemical engineering involved extensive chemistry and rote memorization, with limited career prospects. This perception made me hesitant to pursue it.

By a fortunate coincidence, Panjab University in Chandigarh had an outstanding chemical engineering program. Financial constraints led me to choose this path over the then-popular computer science or other engineering majors. Thanks to the program’s affordability and the scholarships I received, I could pursue my education. Surprisingly, I fell in love with the chemical engineering curriculum and education. It quickly became apparent that this was my true calling. I thoroughly enjoyed every aspect of it, and it continues to shape my approach to solving scientific and technical problems. In retrospect, my initial concerns were unfounded, as I stumbled upon my passion in a field I had chosen by chance!

In my opinion, “success” is a delicate balance between determination and destiny. One has to attempt to create their own destiny, but then let nature take its own course. It’s actually a philosophy from a Hindu scripture, the Bhagavad Gita – you only have the rights to your efforts, and not the rewards or fruits of it. I think that is something that fundamentally governs me. Give it your best attempt, and then everything else is out of your control.

Your biotech startup, ChakraTech, is still currently in stealth mode, but you have recently begun to pitch for fundraising, coming in third place at a recent pitch competition in San Diego. What can you tell me about your company so far?

We are in early stages of our journey, and I can tell you in very broad terms about what we are doing and how we got here.

The biggest thing that came out of the Industrial Revolution in the 20th century was the introduction of plastics. Plastics fundamentally changed the paradigm. It actually totally moved our society to where it is today – without them, we would not be here! Imagine life without milk containers, shoes, everything – everything has plastics.

However, what was a boon for the 20th century is a bane for the 21st century. They’ve served an incredible purpose, but the truth is, these plastics are accumulating in our environment at an incredible pace.

Growing up, my mom was always concerned about plastics entering our food chain through contact with food, and she preferred to use reusable containers made from materials such as steel, glass, and ceramic. It turns out her hunch was spot-on. Recent studies suggest that an average person is ingesting up to a credit card worth of microplastics every week! The full extent of how these micro- and nano-plastics affect our health and environment is still not completely understood, posing a concerning and largely unexplored risk.

What we do at ChakraTech is emulate ancient microbial processes to create biodegradable plastics. Over billions of years, certain microbes have figured out a way to make a degradable plastic, or polyester. It’s actually a fat reserve for them! Similar to how we get fat and have love handles, for bacteria, they’ll end up making their own version of fat reserves – bioplastics. These bioplastics degrade completely in a short time, typically a year or less, and have the power to totally change the 21st century.

Wow, that’s incredible. Is this a new discovery?

No, this polymer is not a new discovery. The earliest reported sighting of this bioplastic polymer was actually from 1890 in a German textbook! Efforts to commercialize it since 1980s have faltered, struggling to compete with the economics of petrochemical plastics. Yet, the potential for scientific and technological advancement is vast — a direction I planned to explore in academica as a tenure-track faculty member. When faculty search committees didn’t embrace this vision, I remained steadfast and decided to pursue this opportunity through my own startup venture.

Anyway, at ChakraTech, we are taking an innovative approach to make this bioplastic. To understand how, you need to understand what plastic is – a polymer is a chain of monomers, basic repeating units. How does a microbe or bacteria turn monomers into the polymers we want? They transform carbon from food source into “fat stores”. Historically, expensive carbon source such as vegetable oils have been used as carbon source, not only elevating expenses but also threatening food security in low-income countries. This approach renders the technology unaffordable and inaccessible to much of the world.

Well, what else could serve as a great source of carbon? Greenhouse gases. That’s where we come in – we’re going to take these microbes in giant vats, feed them greenhouse gases and get them to create bioplastics. What’s interesting about this is that it solves two problems at once. First, we can repurpose the carbon emissions, namely the excess carbon dioxide or methane that is emitted into the atmosphere, for manufacturing various types of materials and chemicals. Second, the bioplastics degrade naturally! This positions us to bridge two historically very different industry segments – biotech and cleantech/climatetech.

The reality is that plastics aren’t going anywhere. Neither are the carbon emissions for the foreseeable future. But perhaps our technology can help to solve two huge environmental challenges at once!

And no one else is working on this?

Various companies, some for over a decade, have concentrated on solving different aspects of the technology and challenges. While they have achieved some progress, most of them are yet to realize their full potential. This, I believe, is largely due to an insufficient integration of science and engineering.

In my experience, the distinct training backgrounds of engineers and scientists often lead to communication barriers, which translates into insufficient technological advancement. Bridging this gap between basis sciences and engineering is therefore vital for effective collaboration on complex projects. Particularly in the case of bioplastics, biological systems don’t necessarily conform to engineering constraints in terms of scalability. This underscores the fundamental need for an integrated approach, combining process engineering with biology and chemistry, to develop bioplastics in a cost-effective manner.

Fascinating. I don’t know too much about microbes, but I’ve seen a few companies lately using microbes in incredible ways. One such company is up in Escondido, Aquacycl, and they use microbial fuel cells to treat wastewater. The microbes generate electricity and clean water as part of that process.

Is microbial engineering an emerging field? Or has the science simply progressed enough that companies can begin reaping the rewards from microbes in a cost-effective way at scale?

Microbial engineering and biomanufacturing have been around for some time, but they are far from a mature industry, and have a unique set of challenges – including a capital-intensive research and development budget. While still in its infancy compared to the petrochemical sector, it is the future of next generation of sustainable manufacturing!

If you really want to put a start date on it, things started when Alexander Fleming discovered penicillin in 1928. And if you want to be even looser with it, people have been fermenting things pretty much forever! The biotech industry, however, really took off in its current form in the late 1970s with the advent of molecular biology tools, notably when Genentech produced insulin using recombinant DNA technology.

There are different kinds of microbes. There are fungi, bacteria, archaea…and companies have been using them at scale for a while now. One of the well-established companies in this field, Genomatica, based in San Diego, utilizes E. coli to manufacture the precursors for nylon and various other products. The tools and the technology to scale them have actually been available for a while now!

So the tools exist, and companies are using them.

Yes, but there are still significant challenges.

Microbes are natural – they exist in nature. But how do you engineer them to perform their best? How do we get it to do what we want it to do, not what they want to do? We want them to produce the maximum amounts of our product, whatever that might be, not what the microbes wants to produce. Microbes have billions of years in their favor. It simply boils down to finding a way to get your microbes to do what you want them to do.

Yet another challenge has been to build a robust scale-up framework, so that the microbes behave in the same way at an industrial scale as they do in the lab.

You mentioned the environmental pushback with plastics, and how a biodegradable plastic can help solve that problem. But there’s another issue with plastics, which is that they’re endocrine disruptors. Does bioplastic solve this problem?

Great question!

Honestly, I think that bioplastic is our best shot at solving this problem. Based on the 2018 EPA statistics, less than 8% of things get recycled. The plastic itself isn’t getting recycled like we think it is! Moreover, recycling itself generates microplastics, which end up in the soil or in the ocean. If you eat a fish that’s has consumed microplastics in the ocean, these microplastics will enter into your body. Same thing when you drink soda out of a plastic bottle. Plastics used in food packaging are a source of microplastic contamination, gradually leaching tiny particles into our food.

Our truly degradable bioplastics breaks down into its simplest, harmless form (technical term is monomers) in a relatively short time span and our bodies are able to tolerate this! It’s not like the plastic in a soda bottle which our bodies don’t make. Our bioplastics are biocompatible, since our bodies already make the base unit that make the bioplastic. Interestingly, there are already implants and sutures made out of this bioplastic since it’s not foreign to our body!

As an extremely early stage startup, you are prone to lots of risk. What are some obstacles you are currently navigating, and what are you doing to create resilience in this fledgling company?

That’s a good question! Transformative endeavors inherently carry risks, yet it is these very ventures that redefine our world.

In the realm of hardtech start-ups, we typically encounter three broad risk categories: scientific/technical, team/execution, and market dynamics.

Firstly, the bioplastics technology we’re focusing on, initially commercialized in the 1980s, has evolved significantly. Earlier, its adoption was limited due to high production costs. Our current objective is to refine this technology scientifically and technically to make it more cost-effective, thereby unlocking new opportunities.

Next, regarding team and execution, we’re consciously assembling an interdisciplinary team with deep expertise in science, engineering, material science, and business development. It’s essential to achieve a harmony between scientific rigor and robust business strategy.

Lastly, market risks can’t be overlooked. Past instances in this industry reveal that premature scaling in absence of market demand or acceptance can lead to failure. Over 40% of start-ups fail due to inadequate product-market fit, a trend even more frequent in our particular field. Hence, we’re prioritizing product development and forging key partnerships to ensure our product meets market needs.

What is next for you, personally, workwise, and otherwise?

I’m looking into transitioning into doing this full time – if you work on ideas part-time, the company will stay part-time.

There is burgeoning start-up scene in India, and I have considered moving back to India to pursue a startup related to bioplastics or other independent ideas. But there are currently other bottlenecks in India which would take longer to resolve. Certain tasks might take five years to accomplish there, tasks that would only require a year or two in the US, especially the research and development (R&D) part. Consequently, I’ve learned to exercise patience in these situations. US has an excellent ecosystem for supporting tech start-ups, so it is a great place to pursue innovation and works out favorably for us.

At this early ideation stage, our focus is on establishing a strong foundation that encompasses both technical and business aspects, as well as assembling an interdisciplinary team. We have an impressive global team of scientists and engineers working on this idea already. Friends and former colleagues in the US, Europe and India who have decades of professional science and engineering experience are helping us too. We are actively working to get advisors on-board with a diverse range of experience, spanning science and technology, government and international policy, business, and finance.

You mentioned deciding on the United States vs India for some of this, and have people all around the globe who want to help. Can you talk about why you’re in San Diego, and any pros or cons that you see in this community?

I think there’s a very big spirit of kindness and generosity in the greater San Diego area, which resonates deeply with me. Furthermore, people are really environment conscious and there is a great ecosystem to support the startups.

San Diego is one of the top three cities in the US to pursue startups, especially in technology and biotech sectors. However, it appears to me that compared to other major hubs such as the Bay Area, NYC, or Boston, we are still lagging in terms of the overall support and funding opportunities for hardtech startups. In addition, there are not many startups in the field of industrial biotech, but I am hoping the success of companies like Genomatica will pave the path for others to follow.

Well Ravi, I hope that you do succeed. What is the best way for someone to contact you if they’d like to learn more?

Thank you. You can find me on LinkedIn! I check it pretty often, so I will be responsive.

Want to learn more? Go more in depth here:

Scripps Research Profile on Ravi Chawla

Leave a comment